Custom Dry Food Blending And Packaging

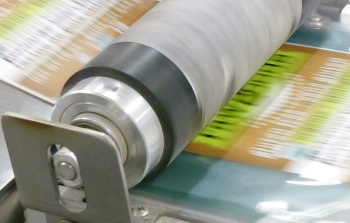

High-quality Food Blending Services

Our SQF certified and allergen free dry blending facility is ready to help you be a leading brand in the food industry. Be it your custom formula or one of our exceptional products available for your corporate brand, we guarantee excellence every step of the way in the dry material blending process.

We not only offer quality equipment and materials for dry blending, we can help you improve your food products to make sure they are safe for human consumption. Our process ensures consistency in all your mixtures and powders.

What is dry blending?

Dry blending, also known as dry mixing, is the process of incorporating dry ingredients to create a well-blended dry product using dry blenders (A paddle, tumble, vertical, or ribbon blender). Our dry blending process is unique because our facility is free from the top 14 allergens of sesame, nuts, gluten, soy, crustacean, eggs, fish, shellfish, mustard, celery, peanuts, milk, sulfate, soya, and lupins.

Request Information

Have a quick question or just ready to start the conversation? Complete the form, and we’ll respond shortly.

Dry Blending

Dry blending for all your retail, bulk and industrial needs.

Co-Packing

Several packaging formats available in various sizes.

Private Label Food Manufacturing

A vast array of products ready for your corporate brand!

Restaurant and Food Service

Whether it’s your products or ours, we offer bulk products and packaging

Why partner with Taylor Gleason Enterprises?

Our entire team is committed to quality, safety, and excellence. Some manufacturers that produce private labels don’t keep their facility 100% allergen-free. Our dry blending process is guaranteed safe for your customers by using highest quality ingredients with a clean production line, whether you’re packaging flour, sugar, powder, salt, or other dry ingrediant blends.

Product Capabilities

- Dry blending

- Baking mixes

- Spices & rubs

- Coatings

- Rice blends

- Pastas

- Protein powders

- Sports drink powders

- Single serve Solo cups - cereals, dry soups, etc.

- Excellent taste

- And much more...

Packaging Formats

- Flexible pouches

- Bag-in-box

- Club packs

- Bulk bags

- Single serve Solo cups - cereals, dry soups, etc.

- And much more...

Ready to get started? Tell us more about your private label needs.

We are gluten-free, USDA Organic, Non-GMO Project Verified, Whole Grain, and Kosher certified.

Our SQF certified facility turns out the safest and cleanest products on the market.

FAQ's

What are the advantages of dry blending?

There are many advantages of dry blending. It is cost-effective and reduces the time of production. It can improve the quality and consistency of the product. Plus, it can enhance the functionality and stability of the product.

What is the process of dry blending?

The process involves loading the dry ingredients into a suitable blender, mixing them at the desired speed and time, and discharging the final product.

What is a dry blending of ingredients?

A dry blending of ingredients is a mixture of two or more dry ingredients that are combined to form a homogeneous product. For example, a dry blending of ingredients can be a seasoning mix, a cake mix, a soup mix, etc.

What is the best dry blending for a blended diet?

The best dry blending for a blended diet depends on the individual’s nutritional needs, preferences, and tolerance. You need high-quality, nutrient-dense, low-fiber dry ingredients. Avoid ingredients in sugar, fat, and salt.

Does dry blending vegetables destroy nutrients?

Dry blending vegetables does not destroy nutrients but may reduce some of them. It can also increase the bioavailability of some nutrients, such as fiber, beta-carotene, or lycopene.

What are the best blenders to buy?

The best blenders to buy depends on the user’s purpose, budget, and preference. However, power, capacity, features, and design are also important factors you should consider when buying the best blender. At Taylor Gleason Enterprises we use top of the line Dry Blenders to provide the best high-quality blending services available.

What is the difference between blending and mixing?

Blending and mixing are different processes with some similarities. The main difference between blending and mixing is the degree of homogeneity and the type of motion.