What is dry blending? How do you blend dry powder?

Granular solids are often combined and blended in a variety of industrial operations. Although small-scale fusing and blending processes were used in the dawning of human civilization (for instance, blending flour, salt, yeast, and water to make bread), today’s complex assembly lines simply require robust processes with swift blending times, versatile machinery, simple cleanup techniques, and commitments that demixing (i.e., segmentation) doesn’t generate a material that has just been combined.

Although the terms blending and mixing are sometimes used synonymously, they are slightly different. The act of thoroughly combining several ingredients to make a cohesive product is known as mixing. The mixture is often a mix of various components (such as sugar and salt), though occasionally a chemically homogeneous substance is mixed to evenly distribute its wide range of particle sizes. On the contrary, Combining materials is sometimes known as blending; however, blending often takes place slowly and with several different ingredients

The pharmaceutical industry and food sectors, in particular, depend largely on mixing and blending technologies. In the pharmaceutical blending industry, components including glucose, viscose, lactose, and surfactants are carefully combined with minuscule amounts of a granular medicinal agent. Cake mix, herbal teas, or spices are some examples of powdered consumable products made by the food industry.

Larger batch sizes, speedier blending periods, and the elimination of segmentation are three critical requirements that mixing and blending technology has successfully addressed over the past few years.

The basic blending technologies, and the variables influencing technological advancements, are all topics covered in this article

What is dry blending?

In the global food sector, dry blending is getting more and more prevalent. The effectiveness, affordability, and flexibility of dry blending are gaining traction in the food and health care industries, sometimes even in unforeseen locations.

In essence, dry blending is what it seems like. Simply stated, in the food sector, this refers to the process of combining dry materials to produce a “dry” output. Dry blending items are simple to manufacture and simple to use. These products can range from condiments to beverages to bread solutions and more.

To make a tasty complement to any meal, you normally just need to add water or another fluid component to the dried powder.

The Benefits of Dry Blending

Dry blending is not only convenient but also extremely economical, making it readily available to individuals. Companies don’t need to charge customers enormous sums of money for something little and delectable because making the dry mix is inexpensive.

Dry blended foods can last significantly longer than any other fresh produce, including packaged food, and are thus even more cost-effective than you might believe because there is virtually little in them that can spoil or go rancid. Additionally, they regularly come in little packs, which makes them very simple to keep because they take a tiny portion of cabinets.

The flavor of dry blend products may cause one to be apprehensive. However, there is no reason to fret because dry blending has no impact on the taste of the components.

Dry blended products can be used to make any meal, and they taste just as wonderful while taking little time to prep and cook.

In a world where people are always on the go, dry mixing dried products aim to enhance nutrient content, taste, and improved efficiency for customers.

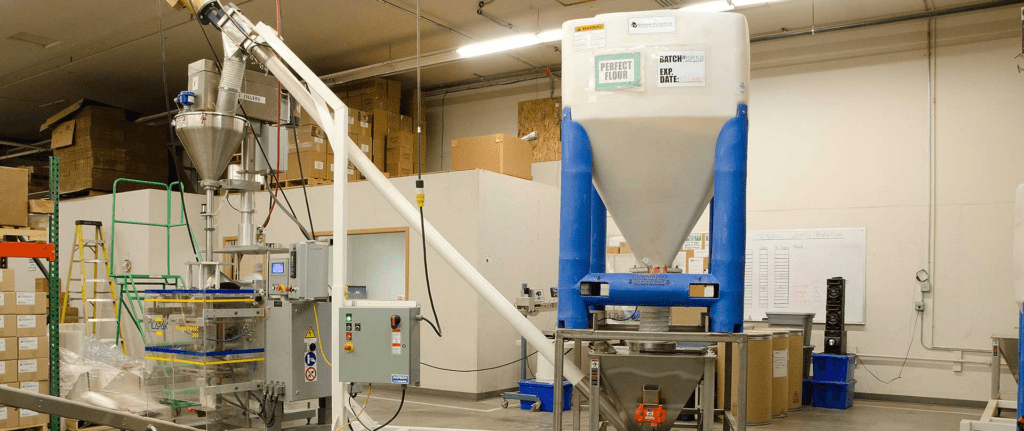

Dry blending process: Different types of blending equipment

Many blending technologies today overlap, making it possible for two or more different types of blending systems to successfully create some products. For a technique to be streamlined, the blender must be chosen properly. Before learning how to choose the finest blending equipment, it is essential to understand the various blending equipment choices.

Ribbon Blenders

The food and drink enterprises frequently use the Ribbon Blender for dry blending. The apparatus comprises a horizontal ditch in the form of a U and a mixer made of internal and external helix ribbons that are adjusted to move materials both radially and laterally.

The design of this blender makes it effective and economical for blending dry ingredients like bread and pancake mix, wheat, loaf enhancers, muesli, trail mixtures, granola bars, seasonings & spices, beverages (powdered tea leaves), coffee ( grounded beans), and other beverage mixes such as whey powder, chocolate drinks, powdered smoothies, and carbonated beverages.

The ribbon blender can be used to prepare plastic resin granules or fluids, such as those used in food plastic films, even though dry blending is its more well-known purpose. Food extrusion is a preparation method that produces a broad array of finished products, including spaghetti, ready-to-eat meals, nibbles, and pet supplies.

During the injection molding process, the ribbon blender’s job is to thoroughly merge two or more granules, cereals, creams, sugar content, emulsifying agents, extrusion guides, and other semi-solids. Water is typically added to the batch after the elements have been combined to bring the moisture content up to the ideal level for extrusion.

Paddle, Vertical, and Tumble Blenders

The Paddle Blender, Vertical Blender, or Tumble Blender are decent choices for blends that need a smoother combining action. A trench in the form of a U is also employed by a horizontal paddle blender. The stirrer is made up of many paddles and has a shorter peripheral contact area than a ribbon, resulting in less strain and low heat generation. The shaft of a vertical blender spins slowly, which culminates in a much milder grinding action than any horizontal mixer. The helical shaft gently lifts material upwards when it turns and circles a cylindrical vessel wall. Particles gently flow backward in regions across the moving helical shaft as they reach the batch’s greatest standard. A revolving appliance known as a tumble blender often features a two-cone or V-shaped construction. There are also asymmetrical containers available that are made to minimize blending time and produce a perfectly homogenized product. Tumble blenders usually run between five to twenty-five cycles per minute. The spinning vessel enables the contents to flow and mix. The impact of blending is quite little.

5 Things to Consider when choosing a blender

How to handle a broad portfolio of formulations and a wide range of diverse components, many of which constitute an antigen risk, is becoming an increasingly challenging task in the powder processing sector. To increase speed and efficiency, some business owners have been ready to invest substantial amounts of money in installing the speediest blenders and stocking lines. However, a high-speed mixer does not always imply that it offers the optimal process solution. Selecting dry blenders from the many kinds available can be difficult and daunting, whether you’re a beginner or an experienced professional. Here are the top 5 things to consider when choosing a blender.

1. Features of the powder

With equal constituent particle sizes, a free-flowing powder will combine without any effort. Here, gentler blending equipment, such as tumble blending or ribbon blending will be beneficial.

2. Batch Size

Blenders don’t always need to be big. Although the blender’s size might be adequate for the order and batch sizes, it is crucial to attach importance to loading times. Take into account any needs for various batch sizes. Ribbon blending will be beneficial.

3. Easy to clean

Making sure that the costly, value-adding elements don’t get “missed” in the blending process is critical. Consider what could fall out of the blender. All fixed blenders will contain some debris that sticks to the walls, driveshaft, paddles, and bushings or accumulates at the bottom of the mixing basin; this material is then wiped away during cleanup. This is an important, valuable product that shouldn’t be tossed aside.

4. Segregation risk following blending

Even while the material may be well-blended in the fixed mixer, this does not ensure the production of a high-quality product because it must be withdrawn from the mixer. As air is displaced by powder exiting the mixer at this point, the “fines” are carried back up through the powder, which may result in the segregation of the mixture. If there are significant product transfer levels involved, this is even worse. Take into account how simple it is to remove the locked blender. Make sure the mixer empties with no product left behind. Because some powders may be sticky, will have poor flow qualities, and are likely to become stuck, take into account the size of the outlet point’s mouth.

5. Blending time

Never believe statements that a blend takes only 3 to 4 minutes. It’s essential to consider the entire end-to-end procedure of mixing, from loading the mixer to discharging it and prepping it for use again. Although blending may only take 3 – 4 minutes, loading and prepping may take about two hours and 3 hours, respectively, making the total blending duration up to five hours and four minutes.

Bottom line

Mixing and blending technology has advanced significantly in recent years to meet typical demands such as larger lot sizes, speedier mix durations, and segregation reductions. Even though various blenders can mix a multitude of powders, choosing a blender is still largely a matter of preference due to the numerous factors at play; the first quantitative approach is still lacking. The possibility for food and healthcare organizations to evaluate processes, improve productivity, enhance uniformity, and augment developments is provided by adaptive improvements in blending technologies. You may choose the appropriate sort of mixing system for your needs by working with a trusted and knowledgeable equipment manufacturer on a thorough testing regime.

FAQ'S

What are dry blend materials?

Dry blend materials are a mixture of powdered or granular substances combined without using a liquid. This blend is typically used as a precursor for various industrial processes.

What is the dry blending of ingredients?

Dry blending is mixing powdered or granulated ingredients without using any liquids. It creates a consistent mixture for various uses.

What are the different types of blending process?

Different blending processes include convective, diffusive, and shear blending. Convective relies on fluid motion, diffusive involves molecular mixing, and shear uses physical force.

What is the difference between mixing and blending powder?

Mixing means combining two or more powders without changing their properties, resulting in an ununiform mixture. Blending, on the other hand, involves a uniform composition, ensuring consistent quality and performance.

Which equipment is used for dry blending?

Some of the standard equipment used for dry blending include ribbon blenders, paddle mixers, or tumbling mixers to mix ingredients thoroughly.